Карактеристики на нашите 1000watt laser machine

1.Stability and reliability of light path system and control system

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours

3.Higher cutting quality and efficiency ,cutting speed is up to 80m/min with appearance and beautiful cutting edge

4.German high performance reducer,gear and rack;Japanese guide and ball screw.

Applicable Industry and materials of машина за сечење со влакна со влакна

машина за сечење со влакна со влакна апликација:

metal cutting, electrical switch manufacturing, aerospace, food machinery, textile machinery, engineering machinery, locomotive manufacturing, agriculture and forestry machinery, elevator manufacture, special vehicles, household appliances, tools, processing, IT manufacturing, oil machinery, food machinery, diamond tools, welding, welding gear, metal materials, decoration advertising, laser surface treatment of foreign processing services, such as all kinds of machinery processing industry.

Нашиот машина за сечење со влакна со влакна's Application Materials:

Professional used to cut thin sheet metal, in a variety of high quality 0.5 -3 mm carbon steel sheet cutting, can also be cutting stainless steel plate, aluminum alloy plate, galvanized sheet, electrolytic plate, silicon steel, titanium alloy, aluminium zinc plate and other metal.

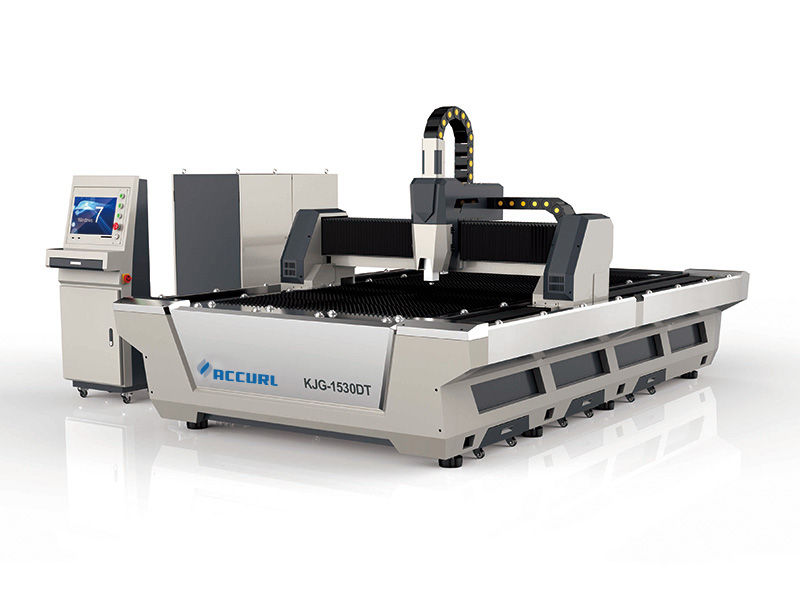

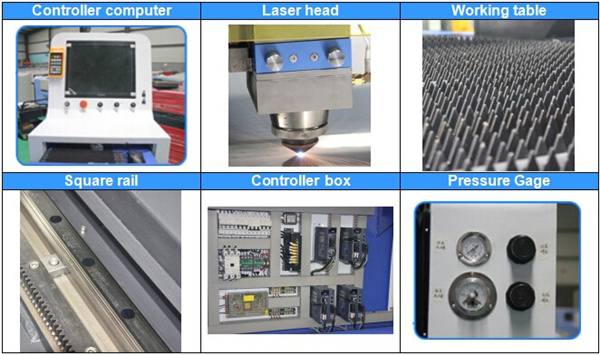

Main machine pictures of 1kw laser cutting machine

Брзи детали

Апликација: Ласерско сечење

Состојба: Ново

Тип на ласер: Ласерски влакна

Применлив материјал: Метал

Дебелина на сечење: 0-20мм

Површина за сечење: 1300 * 2500мм

Брзина на сечење: 25м / мин

ЦПУ или не: Да

Начин на ладење: Ладење на вода

Control Software: bechoff ( Cypcut )

Поддржано за графички формат: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Сертификација: CE, ISO, SGS

Обезбедена услуга по продажбата: Инженери достапни за сервисирање машини во странство

Model: 1000 watt laser

Материјали за сечење: Нерѓосувачки челик јаглероден челик и др (метална ласерска машина за сечење)

Fiber laser Generator type: Famous brand Raycus ( Made in China )

Fiber Laser cutting head: Lasermech ( From U.S. )

Motors & Drivers: 1500W Fuji servo motor made in Japan

Min. Line Width: ±0.02mm

Working life of fiber module: More than 100000 hours

Warranty time: Whole machine for 3 years (fib

Parameter of our Ласерска машина за сечење влакна

| Machine Model | 2500 * 1300мм |

| Ласерска моќност | 300W/500W/1000W/3000W |

| Fiber laser Generator type | Famous brand Raycus ( Made in China ) |

| Ласерска бранова должина | 1064nm |

Laser Beam quality | <0,373mrad |

| Работна табела | Sawtooth |

| Fiber Laser cutting head | Lasermech ( From U.S. ) |

| Focus lens | Lasermech made in USA |

| Working life of fiber module | More than 100000 hours |

| Motors&Drivers | 1500W Fuji servo motor made in Japan |

| Редуктор | 3 sets from Germany |

| Guide Rails | High accuracy PMI brand from Taiwan |

| Transmit system | Dual Rack & Pinion type |

| Rack system | Germany rack |

| Chain system | Igus made in Germany |

| Water Chiller | TEYU( S&A) brand, CW6000 |

| Контролен систем | Professional laser control system--Cypcut

|

| Position type | Red Dot |

| Дебелина на сечење | ≤3mm(stainless steel) ≤6mm(carbon steel) |

| Max. Idle Running Speed | 1400mm/s |

| Брзина на сечење | 300 mm/s |

| Точност на позицијата | 0,05 мм / м |

| Брзина на позицијата | 20м / мин |

| Мин. Ширина на линијата | ± 0,02 мм |

| Потрошувачка на енергија | K12KW |

| Carry weight | 700 кг |

| Напон | 380V/50HZ,3PH |

| Auxiliary Gas for cutting | Oxygen, Nitrogen, Air |

| Compatible software | Autocad, Coreldraw, etc |

| Graphic format | Nc |

| Working method | PC control |

| Total power protection rating | IP54 |

| Тежина на машината | About 4000KG |

| Големина на машината | 4800*2600*1800mm |

| Warranty time | Whole machine for 3 years (fiber module 2 years ) |

Quality control of 1000watt laser

Quality is our sincerest respect offered to all our customers, and it is the most important factor to maintain long-term business relationships with us.

We always pay more attention to the quality of laser cutting machine. Standard quality control system and team are responsible to insure the product quality in every process with different instruments like laser interferometer and laser power meter.

In the mechanical assemble process, the laser interferometer, laser collimator, dial indicator and marble plate are used; In the laser assemble process, the laser power meter and optical microscope are adopted.